Pipe Cleaning Nozzles

CLEANING NOZZLES

Pipe and Channel Cleaning nozzles comes in many different shapes and styles or types and have distinct levels of efficiency. They are used in both storm and sewer (drain) pipes and channels. Cleaning nozzles working with high efficiency are more costly than less efficient standard nozzle. The investment of a high-efficient cleaning nozzle will quickly be a big money saver, due to saved water, diesel, less service of the jetting truck and person-hours.

With increased environmental awareness, it is easy to understand that the need to use less diesel and water, to get the job done, do not only minimize the environmental impact but also minimize operational costs. The trend is to calculate the total operational costs instead of only looking at the purchase cost of the nozzle.

These category of Cleaning nozzles include specific types of designs depending on the cleaning task. All cleaning nozzles need to have the power to move material in pipes. They come with different names like; Bomb, Grenade, Bulldozer, Flounder, Floor Cleaners, Torpedo, Heavy cleaning Nozzles, Traction Nozzles, JAWS®, BL SWIPER®, C-RAY®, MANTA® or simply Powerful Nozzles.

Tier 1 Cleaning nozzles are the simplest version with less efficiency and shortest service lifetime. This is due to the drilled holes for water outlet in the nozzle body. When the drilled holes wear out, the entire nozzle becomes much more inefficient. Tier 1 cleaning nozzles have their place. Smaller diameter pipes and pipes with bends (30˚/45˚/90˚), where nozzle size is crucial and where more advanced nozzles, due to their size, might have difficulties to pass.

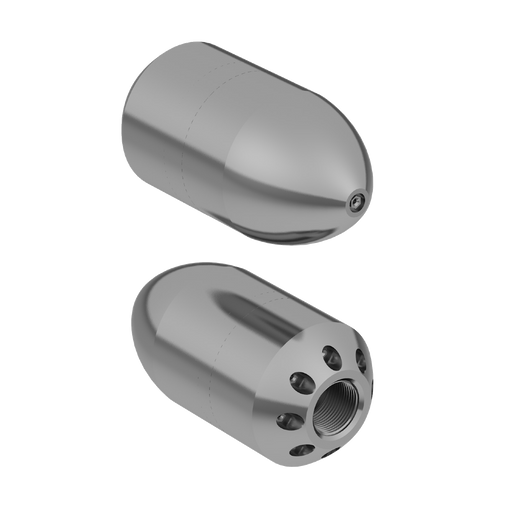

GLOBAL™ GR and GLOBAL™ MF are two extremely popular Tier 1 cleaning nozzles. With a round and flexible design booth types perform among the top in Tier 1 segment.

STANDARD NOZZLE GR are also used in cases where a smaller nozzle is required, i.e., smaller pipes or pipes with difficult bends.

Cleaning nozzles in the Tier 2 classification, are designed for more general cleaning, where the amount of debris in pipe is less. Tier 2 nozzles have no scientific interior design but are supplied with exchangeable jet inserts. If the jet inserts have a superior design that improves the performance as compared to Tier 1 nozzles. Examples of Tier 2 cleaning nozzles are MULTI-GLOBAL®, FIR®POINTED, GLOBAL®SP, GOBLIN® GRENADE and MULTI-GLOBAL® Guided nozzle. MULTI-GLOBAL® Guided nozzle allows guidance of the nozzle from mainline into the lateral.

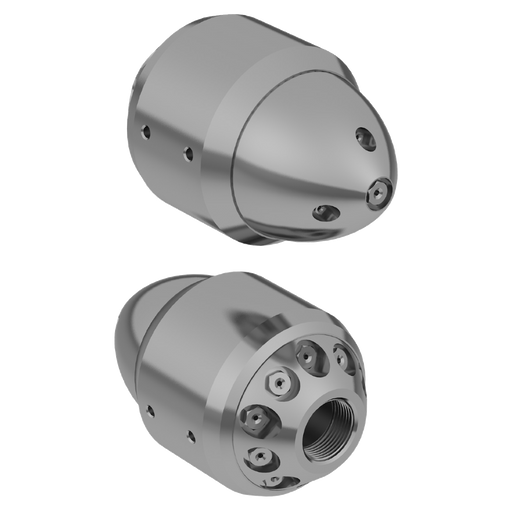

Tier 3 cleaning nozzles have an interior design reducing turbulent flows and pressure drop inside the nozzle when water pass through. The design, together with exchangeable jet inserts, reduces the total water consumption and allow lower rpm on the truck. Efficient, long, well gathered thrusting rear water jets, available at different angles, give the perfect solution for each individual cleaning project. Example of Tier 3 cleaning nozzles are the GOBLIN® series. They are available with rear jets angled 0˚, 0˚+ 2˚, 0˚ + 5˚, 10˚ + 30˚ and 15˚ + 30˚. The outer design of GOBLIN® resemble the design of a Grenade or Bomb. The difference is the inner design where GOBLIN® is a Tier 3 nozzle while most Grenades and Bombs are Tier 2, i.e., without any water directing design inside the nozzle.

Tier 4 cleaning nozzles (Europe only) normally are more costly but quickly pay off in saved costs of diesel, water as well as wear and tear on the jetting unit, also in the cost of labor of the time spent on the jobsite. Tier 4 nozzles clean pipes in half the time compare with a Tier 3 nozzle and at least four times faster than a Tier 2 nozzle.

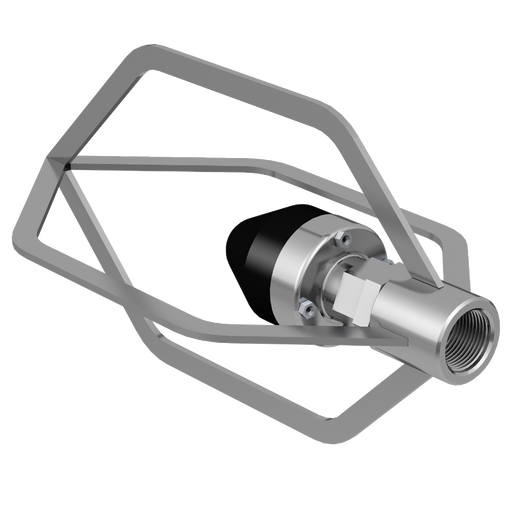

BL SWIPER®, C-RAY®, MANTA® and JAWS® all belong to Tier 4. They have an interior design with an advanced scientifically technology, controlling the water when passing resulting in low turbulence and pressure drop inside the nozzle.

Tier 4 cleaning nozzles are the obvious choices when the focus is on time, money, efficiency, and environmental considerations.

-

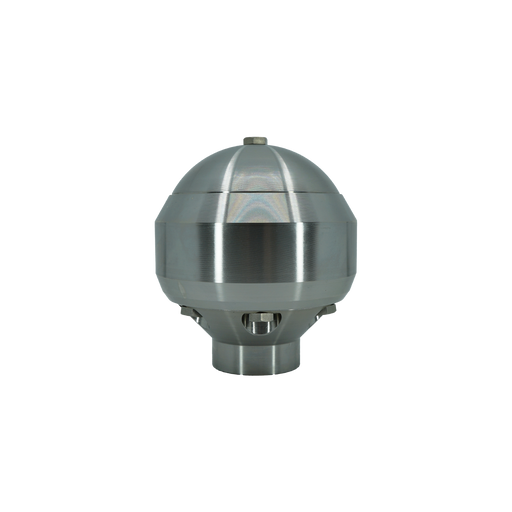

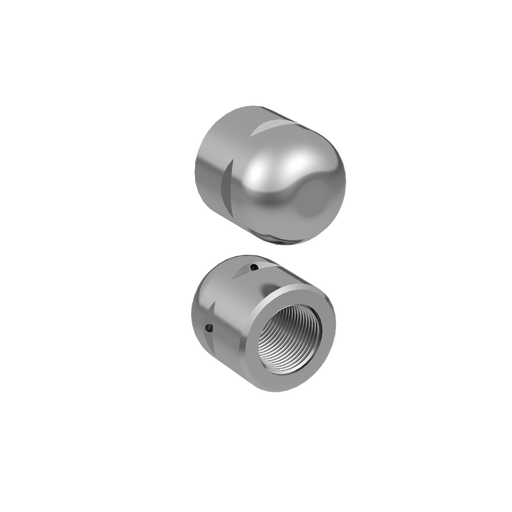

360° Grenade-bombs

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /This enz® jet nozzle is made of wear-resistant hardened steel. The "grenade" and the "bomb" are joined in the same nozzles. Different jet angles pe...

View full details -

GLOBAL™ GROUND

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /GLOBAL™ GROUND is our lightweight and compact everyday nozzle to be used to remove material in pipe such as sludge, sand, and minor stones. This ...

View full details -

GLOBAL™ SP

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /GLOBAL™ SUPER PENETRATOR has a substantial amount of weight so it sits low on the bottom of the pipe. The specific design minimizes risk of nozzle ...

View full details -

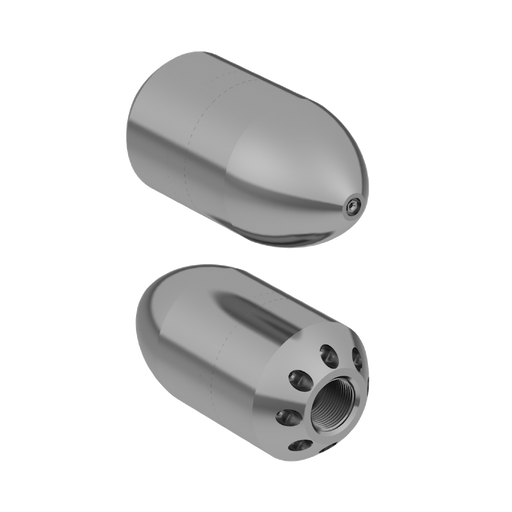

GOBLIN® 0°

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /GOBLIN® with 0˚ degrees rear jets has a weight of 3,6 kg (8 lbs) and is supplied with 8 rear jets 0˚ and one front jet. The front jet can be plugge...

View full details -

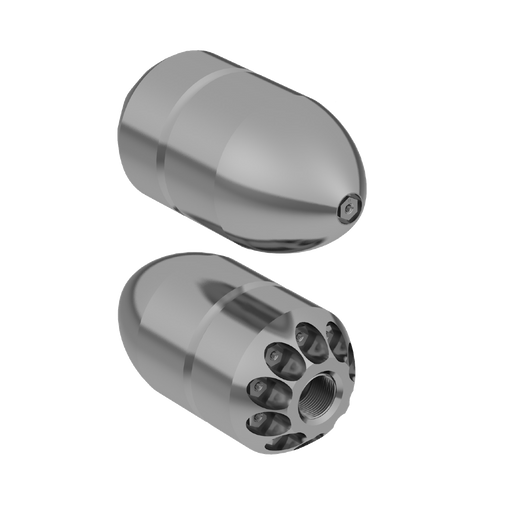

GOBLIN® 0° + 5°

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /GOBLIN® 0˚ + 5˚ degrees with 8 or 10 rear jets (depending of connecting size + one front jet optional), is often used to removal heavy material whe...

View full details -

GOBLIN® 10° + 30°

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /GOBLIN® 10˚ + 30˚ has a wide range of uses and can be seen as a "universal pipe cleaning nozzle". This is due to the combination of 10˚ and 30˚ ang...

View full details -

GOBLIN® 15° + 30°

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /Grenade or Bombs are the general working names in the business for this type of nozzle. The rear jet angles of 10˚ or 15˚degrees in combination wit...

View full details -

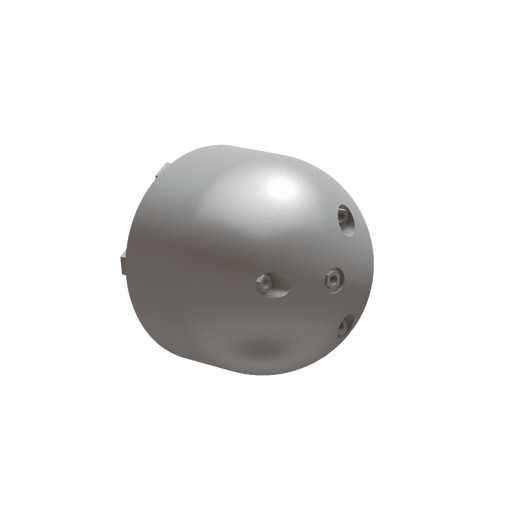

GOBLIN® GRENADE

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The GOBLIN® GRENADE is made in harden stainless steel and is engineered for optimum maneuverability and to prevent nozzle from getting stuck on off...

View full details -

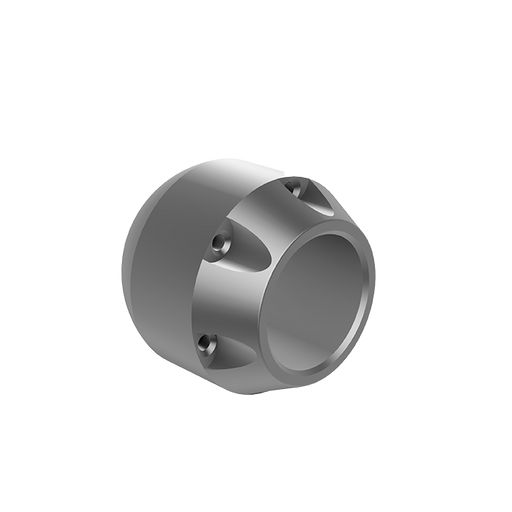

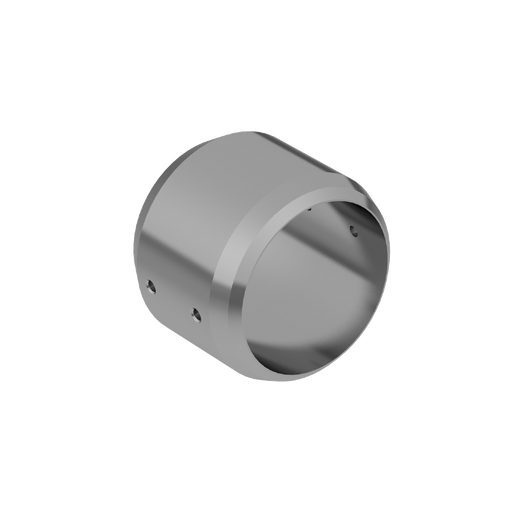

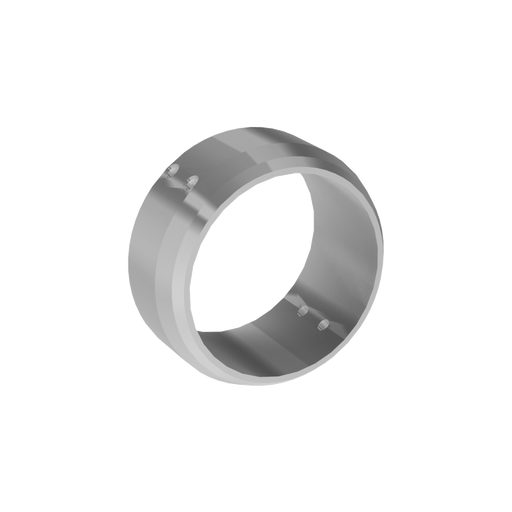

GOBLIN® wearbody

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /GOBLIN® Wearbody, manufactured from harden Stainless Steel. The GOBLIN® wearbody fits only 2-11655-15-30-xx-xx.

-

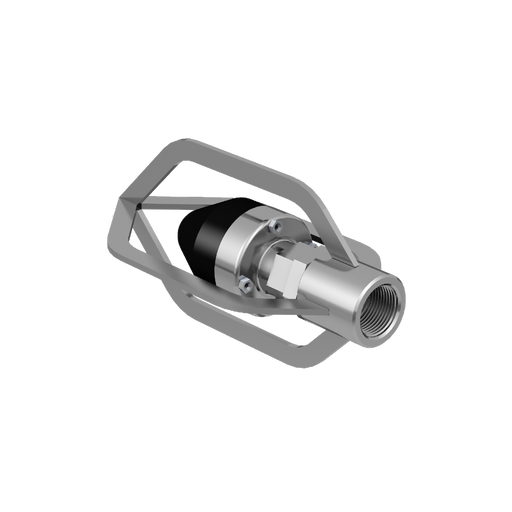

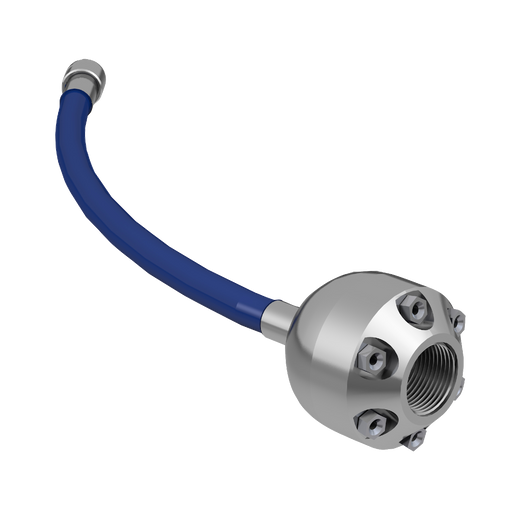

JAWS®

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The JAWS® is one of our most recognized and appreciated pipe cleaning nozzles. Thousands of skilled pipe cleaning operators are using the JAWS® all...

View full details -

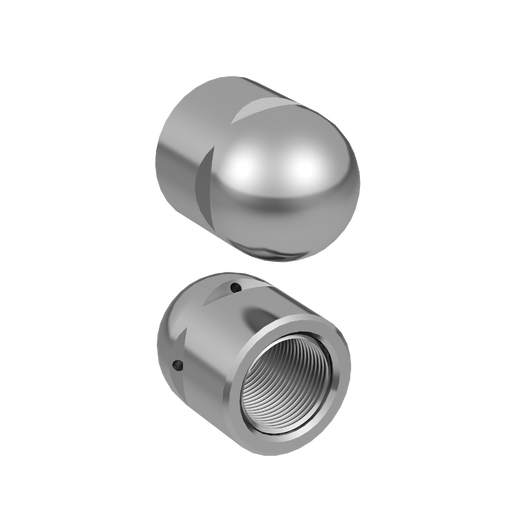

JAWS® 100

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /JAWS®100 is the smaller version of the JAWS® made with same quality and design as the larger version (quality Swedish stainless steel with a protec...

View full details -

JAWS® 100 Accessories

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| / -

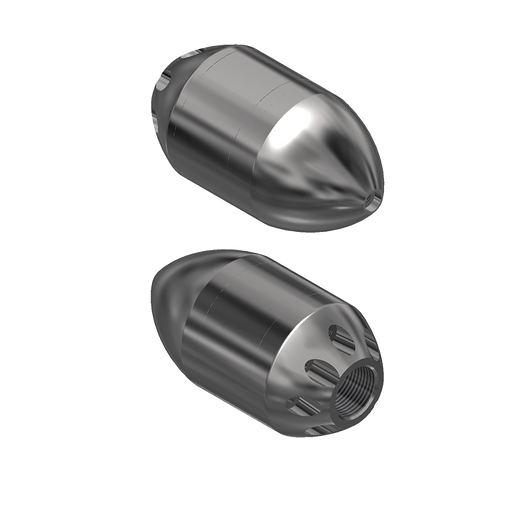

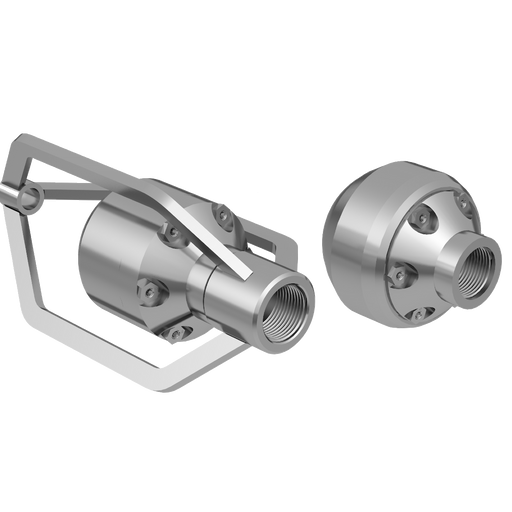

JAWS® RC

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /JAWS® RC cleaning nozzle is made of high quality stainless steel. We have developed a new technique allowing us to mill the channels directly in th...

View full details -

JAWS® RC Accessories

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| / -

MULTI-GLOBAL®

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /MULTI-GLOBAL® sewer penetrating nozzle is a spin off from our popular GLOBAL® series of nozzles but has replaceable orifices. MULTI-GLOBAL® sewer n...

View full details -

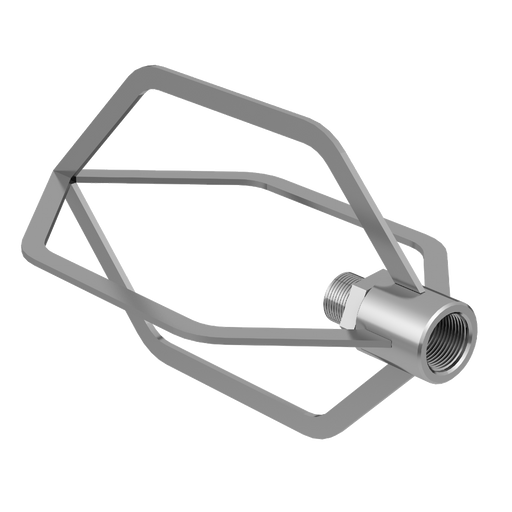

MULTI-GLOBAL® Guided cleaning nozzle

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /MULTI-GLOBAL® GUIDED CLEANING NOZZLE is constructed to allow the cleaning nozzle to travel info connecting pipes e.g. from the mail line into the s...

View full details -

Standard nozzles Ground

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /Our Standard Nozzle Ground are used for cleaning pipes to remove lighter material in pipe such as sand and sludge. With no front jet(s) and only su...

View full details