Rotating Nozzles

When the inner surface of the pipe needs to be cleaned, removing grease, smaller roots, deposits or before relining, using a rotating nozzle is normally the preferred method.

On the market there are two main categories of rotating nozzles – Fast and slow rotating/spinning.

Fast rotating nozzles

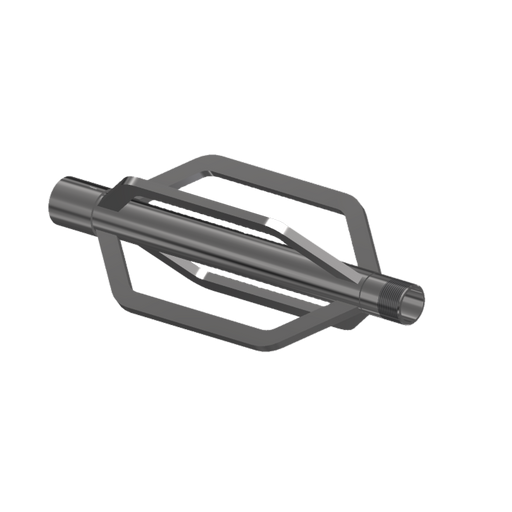

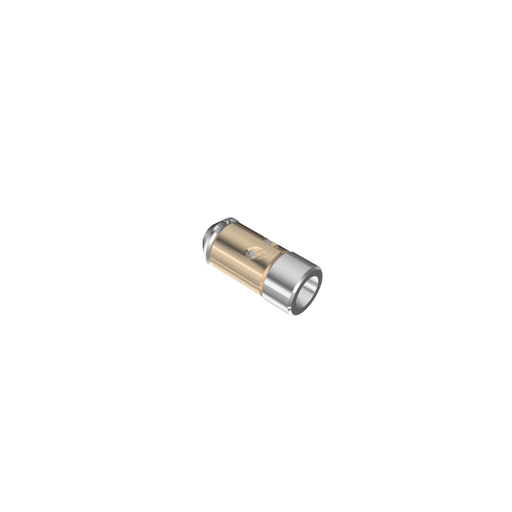

The fast-rotating nozzles consist of a thrusting part with a shaft. On the shaft a rotating body is mounted and held into place by a cap. The rotating bodies are available in a variety of designs and with different water jet angles on the body. Not all fast-spinning nozzles have thrusting rear jets. Then the rotating body normally is supplied with lower jet angles, which not only clean the inner diameter of the pipe, but also thrust the nozzle up the pipe. To choose a spinning nozzle without thrusting rear jets is suitable when nozzle does not have to travel far into a pipe. For longer distances, we recommend rotating nozzles supplied with thrusting rear jets.

The fast-rotating nozzles use the water supplied by the high-pressure pump not only for the actual pipe cleaning process but also to create a gap between the rotating body and the shaft to minimize friction. Due to this construction fast spinning nozzles are therefore normally not suitable or recommended for used on recycling trucks. The reason is that recycling water contains particles that could suddenly stop the rotating motion and damage the material of the nozzle. Therefore, the fast-spinning nozzles are not suitable or recommended for use with recycling water.

Due to the fast rotation the water jets quickly fall apart after leaving the spinning part. The rotation speed varies but can be up to 3,000-5,000 rpm.

Slow Rotating Nozzles

There are many different slow-rotating nozzles on the market, e.g., Bulldog. Slow-rotating nozzles use various technical design solutions to slow down the rotation speed significantly compared to a fast-spinning nozzle. Bulldog rotated in a span between 1200 - 5000 rpm dependong on model. This means that the water jets leaving the nozzle stays together longer after leaving the nozzle and thus have significantly greater cleaning power than a fast-rotating nozzle. slow-rotating nozzles are available in several variations, many of which are suitable for use with recycled water.

Vibrating Nozzles

Vibrating nozzles are also included in the group of rotating nozzles. These are of the variant fast-rotating, but the rotating body itself is usually oscillating, i.e., not centered on the shaft. The rotation then creates a form of imbalance that causes the nozzle to "jump" in the line. Some designs have hardox or carbide on the thrusting part and cap.

Knocking nozzles are suitable when, for example, you need to knock loose solidified material at the bottom of the pipe, such as flowable fill or lighter concrete.

-

BL SPINNER® Accessories

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| / -

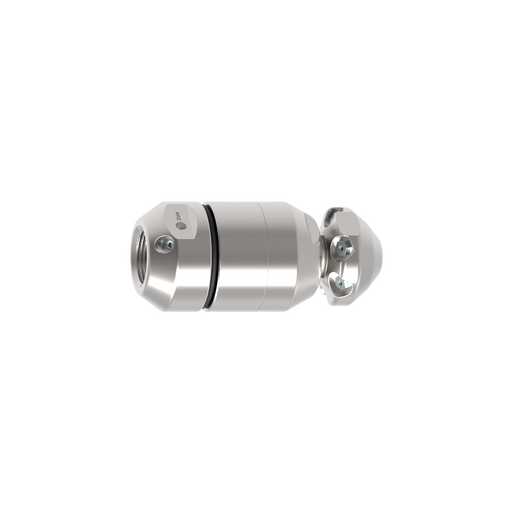

BL SPINNER™

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The BL SPINNER™ series are developed for a flexible and effective removal of grease, smoother deposits, smaller roots etc. They come in two version...

View full details -

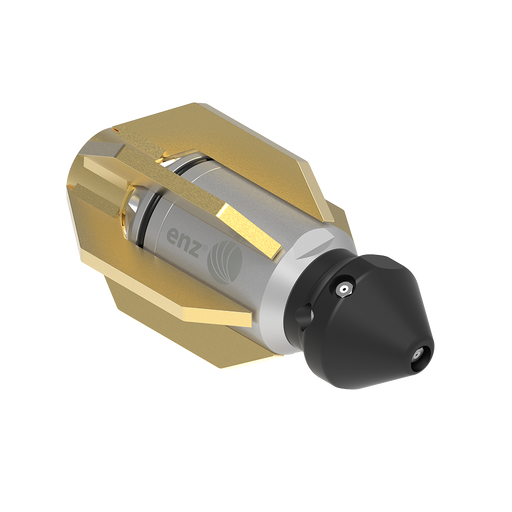

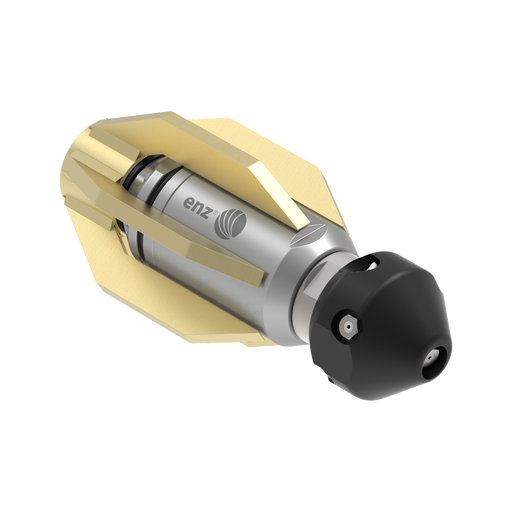

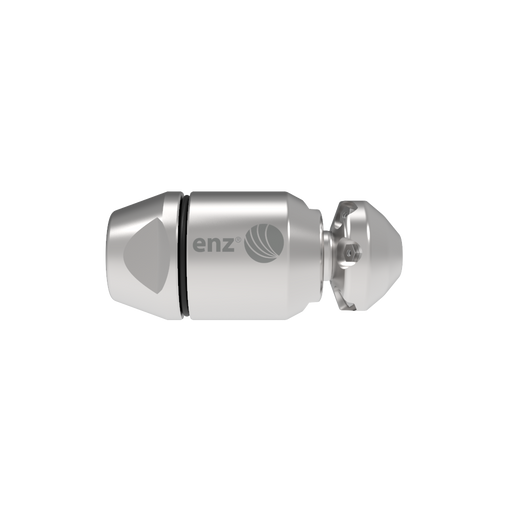

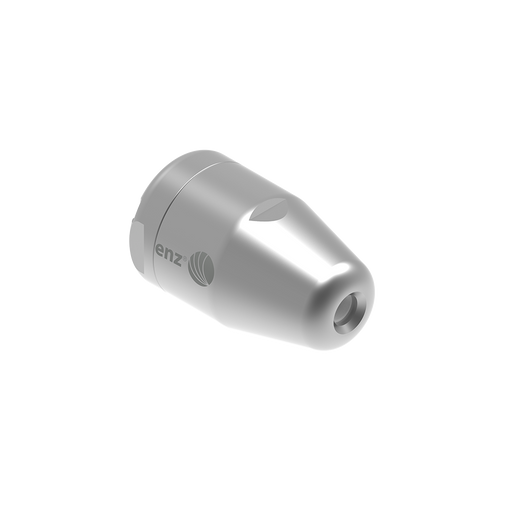

Bulldog 30

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Bulldog® rotating nozzle has been designed for operation with recycling water and fresh water. The cleverly built sliding bearing allows t...

View full details -

Bulldog® 1 1/4"

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Bulldog® rotating nozzle has been designed for operation with recycling water and fresh water. The cleverly built sliding bearing allows t...

View full details -

Bulldog® 1"

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Bulldog® rotating nozzle has been designed for operation with recycling water and fresh water. The cleverly built sliding bearing allows t...

View full details -

Bulldog® 1/2"

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Bulldog® rotating nozzle has been designed for operation with recycling water and fresh water. The cleverly built sliding bearing allows t...

View full details -

Bulldog® 3/4"

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Bulldog® rotating nozzle has been designed for operation with recycling water and fresh water. The cleverly built sliding bearing allows t...

View full details -

Bulldog® Antiblast

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /Cleaning sewer lines when near home installations brings the risk of pressure equalisation through toilets or stench traps. This comes from negativ...

View full details -

Bulldog® Low flow 1/4" - 1/2"

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Bulldog® rotating nozzle has been designed for operation with recycling water and fresh water. The cleverly built sliding bearing allows t...

View full details -

Guiding Nozzles

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /enz® guided nozzle – for precision cleaning of pipe inlets The enz® guided nozzle is specially developed for targeted cleaning of pipe inlets and b...

View full details -

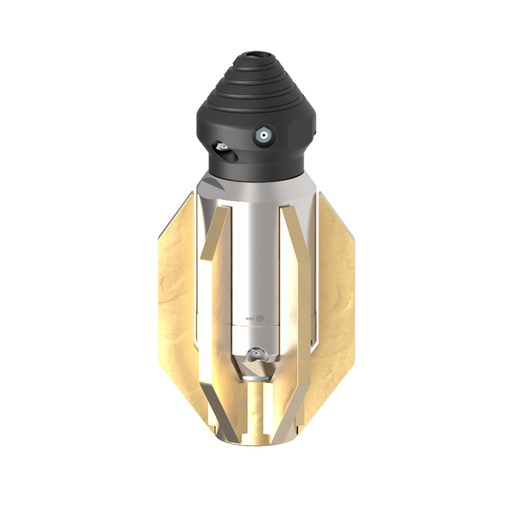

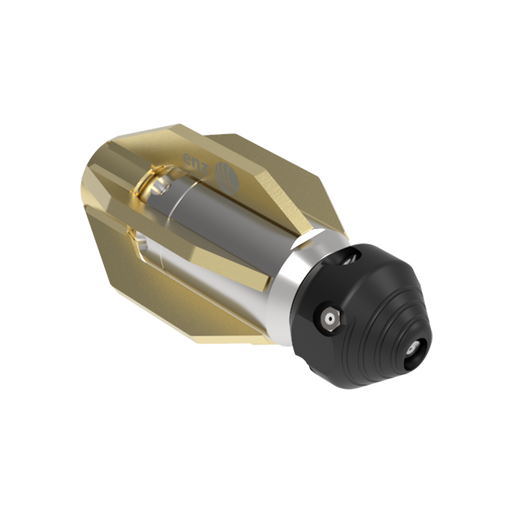

MASTER DRILL™

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The cleaning nozzle is equipped with a powerful rotating front jet, type high pressure cleaner. The powerful and fast-rotating water cone effective...

View full details -

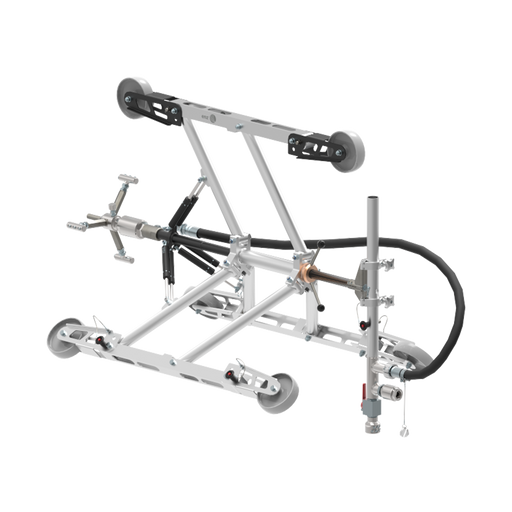

Propeller Nozzle

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /With this enz® tool large channels will be efficiently cleaned. They can be used for dimensions of Ø 600 - 3000 mm. The skids are easy to adjust an...

View full details -

Rotodrill

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The Rotodrill is a universal pipe cleaning nozzle suitable for pipe diameters between 30 and 250 mm, depending on the design. Its special feature: ...

View full details -

Rotojet HRH

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The semi-radial rotating enz® nozzles with their 4 retroacting cutting-jets at an angle of approx. 45° cause simultaneously the cleaning procedure ...

View full details -

Rotojet HRV

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /enz® ROTOJET HRV nozzles with forward impact angle of approx. 45° on the pipe wall as well as a front jet (on request) and 3 retro-thrust jets caus...

View full details -

Rotojet KBR

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /This allround enz® combination nozzle is excellent for flushing out pipes as well as adjoining lateral pipes at any angle. It only requires a very ...

View full details -

Rotojet KBRV

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The nozzle enz® KBRV is provided with 2 semi-radial jets directed forward in an angle of 45°. As a result, this nozzle must either be equipped with...

View full details -

Rotojet RGS

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The radial rotating nozzles enz® are equipped with 4 radial jets of 75° for the pipe cleaning and 3 thrust jets for the advance which at the same t...

View full details -

Rotopuls 16 mm

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® rotating nozzle is provided with an eccentrically supported rotor, which produces very fast vibrations and pulsating jets. The resulting p...

View full details -

Rotopuls Edgy

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® rotating nozzle is provided with an eccentrically supported rotor, which produces very fast vibrations and pulsating jets. The resulting p...

View full details -

Rotopuls Round

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® rotating nozzle is provided with an eccentrically supported rotor, which produces very fast vibrations and pulsating jets. The resulting p...

View full details -

Turbopuls

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The enz® Turbopuls nozzle is provided with an eccentrically supported rotor, which produces very fast vibrations and pulsating jets. The resulting ...

View full details -

Xtreme Tank Cleaner A80R /A80R2

Original price €0,00 - Original price €0,00Original price€0,00€0,00 - €0,00Current price €0,00| /The A80R (Slow) rotating tank cleaner are available from 50-60 l/min. The A80R2 (Fast) self-propelled tank cleaner are available in 60-90 l/min.