Operation to minimize risk of blowing water traps

Basic

When a cleaning nozzle travel through a pipe using water under pressure from a jetting truck, it is not just the water that is being put into motion but also the air in the pipe.

In a pipe, there are often several service lines connected from housing, which are affected by the air flow created when cleaning a pipe. The result may be what we normally call the "blowing toilet effect" and in many cases, is due to the fact that the ventilation on the houses are too small in relation to the air created and pushed into the system when cleaning a main line.

To understand the relationship between pressure and flow in the cleaning nozzle and how it affects the exaction of the nozzle in pipe and the nozzles ability to effectively clean the pipe there are two main rules:

- If you want the nozzle to quickly thrust up the pipe or alternatively thrust a longer distance the pressure in the nozzle needs to be higher.

- If you want optimal cleaning efficiency; clean the pipe as quick as possible with minimal total water consumption and minimal kilowatt consumption (= minimal diesel consumption), you should utilize the high-pressure pump water flow and have a maximum pressure at the nozzle of 60 bar.

How does "blow toilet effect” occur and how is it prevented?

The first critical operation to push water out of the water locking system in toilets etc (blow toilets) occur when the nozzle is thrusted up the pipe. Then an overpressure occurs behind the nozzle. At the same time, the air currents increase around the nozzle, meaning that around a larger nozzle the airflow will be higher compare with a smaller nozzle.

To minimize the risk of blowing toilets, the following measures should be taken:

- Remove the lid on the manhole upstream and, if available, open the cleaning manhole in front of the property.

- Operate an effective nozzle at a lower pressure.

- Select a physically smaller nozzle to equalize pressure in front of and behind the nozzle.

- Select an effective nozzle (Class 4) with long, well gathered jets that throw water further behind the nozzle (designed for minimal turbulence) to be able to work efficient at lower pressure in nozzle at higher water flow.

- Choose a nozzle with fewer and larger jets rather than a nozzle with many small jets.

- When nozzle have been thrusted up the pipe (maybe to next manhole), turn off the water to equalize the pressure in the pipe, before re-starting the water pump again and pull back the nozzle.

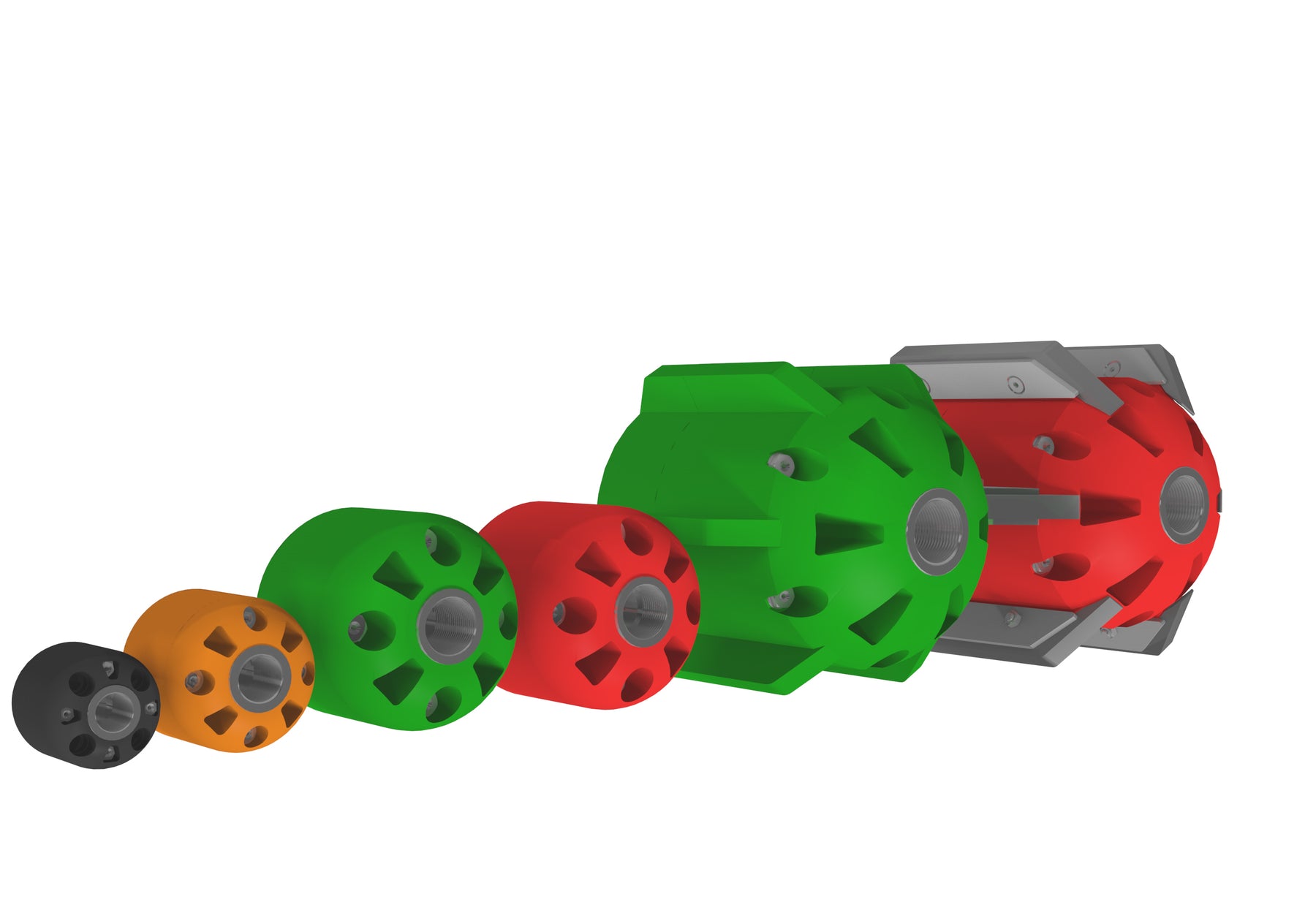

BL Swiper® is a series of nozzles that are advantageously chosen to reduce the problem of blowing toilets.

- With its ejector channels the air is directed through the nozzle, thus reducing air velocity around the nozzle and facilitating pressure equalization in front of and behind the BL Swiper® nozzle.

- BL Swiper® is available in a variety of sizes for easy adjustment to pipe dimension.

- The inner design of BL Swiper®, along with fever water jets, gives extremely long and strong water jets that effectively move the debris in pipe.

- BL Swiper® works effective already at 25-30 bar pressure in nozzle.

The so called “Antiblast” nozzles normally uses an extra ring of jets with a high angel to reduce the overpressure behind the nozzle and decrease the pressure in front of the nozzle, by creating a blocking wall of water for the air to pass. However, due to the high-angle jets, efficiency is poor and results instead of poorer cleaning efficiency and therefore becomes an expensive and ineffective solution.

Conclusion; Cleaning of pipes involves the understanding of cause and effect to be able to use the resources in a cost-effective manner.