Nozzles Tier 2 (Advanced)

We have previously explained the difference between the different nozzle classes. Today we will dig a bit deeper in some of our Tier 2 nozzles.

Class 2 or Tier 2 as it is called internationally is, as you know, a slightly simpler design inside the nozzle without internal control of the water in the chamber but with exchangeable jet inserts instead of simple drilled holes in the nozzle body. Then all Tier 2 nozzles should be equally good? That is certainly not the case. The inner chamber, jets, number of jets, angle of jets, size of the jets… There´s a lot of parameters that can make a big difference in the efficiency of a Tier 2 nozzle.

MULTI GLOBAL®, is one of the best Tier 2 nozzles on the market. It´s available in sizes from 3/8 "to 1-¼" hose thread connection and can be used for many different jobs and assignments. The short and round body makes it easier to get through bends and offsets.

Depending on the setup, you can use the nozzle for different projects, such as:

• Cleaning (pulling or moving materials) - Plug all four front jets and let all the water flow out the back. We recommend about 60 Bar (900PSI) at the nozzle for best results. A tip is to use an extender pipe to prevent it from going in to branches and prevent it from turning in the pipe.

• Universal nozzle, easier clogs - Equipped with three plugs in the front and just one front jet in the center, to open blockage. We put slightly smaller jets at the rear of the nozzle to let the nozzle run at higher pressure. We recommend at least 100 Bar (1450PSI) at the nozzle.

• Ice / heavier clogs - equipped with three jets in the front that are angled towards each other (as a focal point) and a plug in the center. The same principal as above, slightly smaller jet inserts are mounted at the rear to ensure the recommended pressure of at least 100 bar (1450 PSI).

• Cleaning before root cutting or difficult blockage - all four front jets and rear jets are used. By using a setup like this, we get a lot of water in many different angles that are effectively clean up rocks and gravel, paper, sludge, etc. that is stuck in the roots and makes the job difficult for the root cutter and creates unnecessary wear on the cutter. When we use this nozzle to open up a boring path, we use more water directed forward than normal because the propulsion on these occasions is not as important as it is generally shorter distances for nozzle to travel in pipe. Here we set up the nozzle to work at higher pressures, at least 100 bar (1450 PSI).

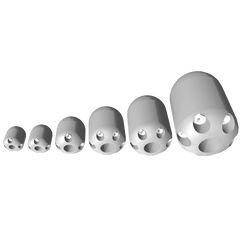

GOBLIN® GRENADE - If you prefer a heavier but still flexible class 2 / Tier 2 nozzle that is lying in the bottom of the pipe and is mainly used for moving material out of the pipes, we recommend our series GOBLIN® GRENADE, they are available with 1/8 "to 1" threads. The 1” can also be used for 1-1/4” hose with an adapter. Its high weight means that, in both smaller and larger pipes, it tends to tip down and avoid getting stuck. But as always, we recommend the use of an extender pipe whenever possible to minimize the risk of the nozzle turning or going into branch pipes etc.

It is mainly set up with only rear jets but can of course also be used supplied with a front jet for easier blockages. It is set up to work at a pressure around 60 Bar (900 PSI) at the nozzle.